The CIP System, Automatic Cleaning System Method

- 14, Sep 2021 12:09

- Heru

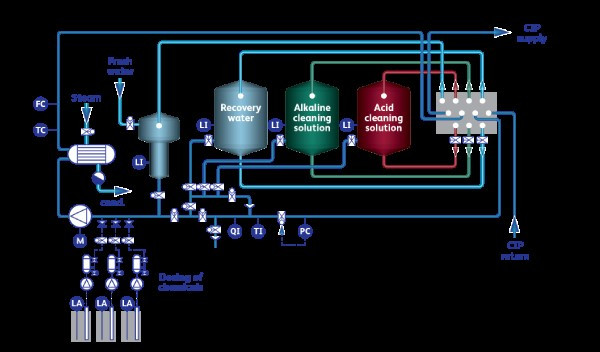

CIP stands for Clean-in-Place is a cleaning system that uses an automatic method, usually this system is used to clean the interior surfaces of pipes, tanks, lines, processing equipment and supplies without requiring an operator to run / clean it or remove and dismantle the equipment, which will consume more energy, time and money.

In the food and beverage industry, CIP is very often used to clean the interior surfaces of food and beverage processing pipes, tanks, freezers, mixers, blenders, homogenizers, toasters, and many more. CIP is used and applied in most industries such as the health industry, bio-tech industry, and many more, this aim to maintain the cleanliness of tools and places as a whole in order to maintain the cleanliness and quality of products according to the specified standards, as well as the safety of consumers who use or consume it. CIP needs to be carried out as often as possible and repeatedly, so the condition of the equipment and place can support an optimal result, also make the equipment lives last-longer.

The CIP system is designed to be applicable to many industries and the standards of each industry. CIP systems can be implied in the portable or stationary, single tank, two or multi tank, dual operating / multi circuit, and single-use only. The purpose of making a CIP system is that we don't have and need to use excessive chemicals, save water and utility costs, save work time, and maintain the safety and security of the operators, or we can say that the CIP system can save the energies, times, and costs for workers and companies.

Industrial equipment like bioreactors and fermenters require the support of a CIP system to make the equipment remain in a clean and stable cycle and condition, so that the results of industrial processing can be maximized and run smoothly. When using CIP, it is necessary to design and measure the right system and good standard in order to ensure sufficient and appropriate water flow and pressure to be able to remove residual impurities thoroughly and effectively.

To help meet your CIP needs in your laboratory or workplace, BiOZEEN offers its CIP system that gives you many benefits, such as:

- The cleaning process in a short time.

- No need to spend more on cleaning fees / costs.

- Water consumption is reduced.

- Automated CIP systems can provide full data logging for quality assurance requirements.

- Space conserving design.

- Skid-mounted (single / double tank system).

- Integrated mobile or split system.

- Flexible range.

- Varying configurations.

- Minimal maintenance.

- Vessel constructions in SS 316L requirement.

- Requisite instrumentation to accord safety.

- PLC control system with HMI or SCADA.

Please visit biozeen.com for more information, or kindly check hartechindonesia.com if your region is in Indonesia. As a distributor for BiOZEEN’s Products in Indonesia territories, we are always ready to serve and support you in providing the best products from BiOZEEN that can help you complete your laboratory or workplace needs.

- 14, Sep 2022 13:43

- 29, Oct 2021 09:23

- 28, Oct 2021 09:53

- 27, Oct 2021 10:25

- 27, Oct 2021 10:20

- 26, Oct 2021 11:05

- 26, Oct 2021 11:00

- 25, Oct 2021 10:37

- 25, Oct 2021 10:32

- 22, Oct 2021 11:30

- 22, Oct 2021 11:27

- 22, Oct 2021 11:21

- 21, Oct 2021 11:58

- 21, Oct 2021 11:51

- 21, Oct 2021 11:44

- 21, Oct 2021 11:36

- 18, Oct 2021 13:02

- 15, Oct 2021 13:37

- 15, Oct 2021 13:33

- 15, Oct 2021 13:27

- 14, Oct 2021 10:58

- 14, Oct 2021 10:36

- 14, Oct 2021 10:31

- 14, Oct 2021 10:27

- 08, Oct 2021 12:11

- 08, Oct 2021 12:06

- 08, Oct 2021 12:01

- 07, Oct 2021 17:24

- 07, Oct 2021 09:57

- 06, Oct 2021 12:29

- 06, Oct 2021 12:22

- 05, Oct 2021 13:35

- 05, Oct 2021 13:30

- 01, Oct 2021 12:01

- 01, Oct 2021 11:44

- 30, Sep 2021 12:55

- 29, Sep 2021 13:48

- 28, Sep 2021 11:43

- 28, Sep 2021 11:38

- 28, Sep 2021 11:35

- 27, Sep 2021 12:21

- 24, Sep 2021 10:40

- 24, Sep 2021 10:37

- 24, Sep 2021 10:32

- 24, Sep 2021 10:27

- 24, Sep 2021 10:23

- 23, Sep 2021 21:42

- 23, Sep 2021 21:34

- 23, Sep 2021 21:29

- 23, Sep 2021 21:25

- 22, Sep 2021 11:10

- 22, Sep 2021 11:06

- 22, Sep 2021 10:44

- 22, Sep 2021 10:38

- 22, Sep 2021 10:24

- 20, Sep 2021 12:09

- 20, Sep 2021 11:53

- 20, Sep 2021 11:45

- 17, Sep 2021 10:16

- 17, Sep 2021 10:10

- 17, Sep 2021 10:02

- 17, Sep 2021 09:51

- 17, Sep 2021 09:46

- 14, Sep 2021 12:45

- 14, Sep 2021 12:35

- 14, Sep 2021 12:29

- 14, Sep 2021 12:25

- 13, Sep 2021 14:59

- 13, Sep 2021 14:54

- 13, Sep 2021 14:07

- 13, Sep 2021 14:01

- 09, Sep 2021 16:16

- 09, Sep 2021 16:07

- 09, Sep 2021 15:57

- 09, Sep 2021 15:52

- 02, Sep 2021 09:24

- 02, Sep 2021 08:29

- 01, Sep 2021 08:49

- 01, Sep 2021 08:33

- 31, Aug 2021 08:46

- 31, Aug 2021 08:25

- 30, Aug 2021 09:40

- 30, Aug 2021 09:20

- 27, Aug 2021 08:52

- 27, Aug 2021 08:14

- 26, Aug 2021 12:08

- 26, Aug 2021 12:00

- 25, Aug 2021 08:32

- 25, Aug 2021 08:17

- 19, Aug 2021 08:37

- 19, Aug 2021 08:19

- 17, Aug 2021 08:40

- 17, Aug 2021 08:27

- 16, Aug 2021 08:31

- 12, Aug 2021 08:57

- 12, Aug 2021 08:41

- 11, Aug 2021 09:40

- 11, Aug 2021 08:50

- 10, Aug 2021 09:05

- 10, Aug 2021 08:47

- 09, Aug 2021 09:46

- 09, Aug 2021 09:08

- 05, Aug 2021 17:19

- 05, Aug 2021 16:08

- 18, Sep 2020 01:54

- 18, Sep 2020 01:50

- 18, Sep 2020 01:48

.jpg)

.jpg)

.jpg)